In the realm of advanced materials, ceramic crucibles for melting stand as a testament to the integration of cutting-edge technology and traditional craftsmanship. As the industrial landscape evolves, the demand for specialized, high-performance crucibles has increased, particularly in Europe and the Americas. This article delves into the intricacies of ceramic crucibles for melting, their unique characteristics, applications, selection criteria, manufacturing process, and real-world case studies.

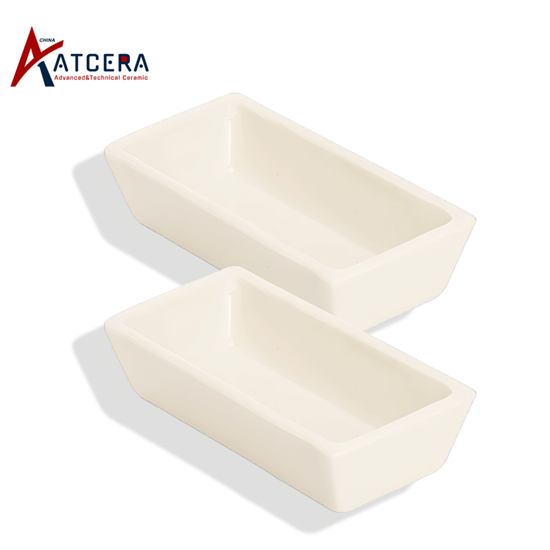

Characteristics of Ceramic Crucibles for Melting

Ceramic crucibles for melting are crafted from high-purity, ultra-fine inorganic compound powders. These materials undergo rigorous manufacturing techniques and structural design to yield crucibles that exhibit unmatched properties. Key among these are their exceptional thermal stability, resistance to chemical corrosion, and superior durability. Additionally, ceramic crucibles boast minimal heat loss, ensuring efficient energy utilization and cost savings.

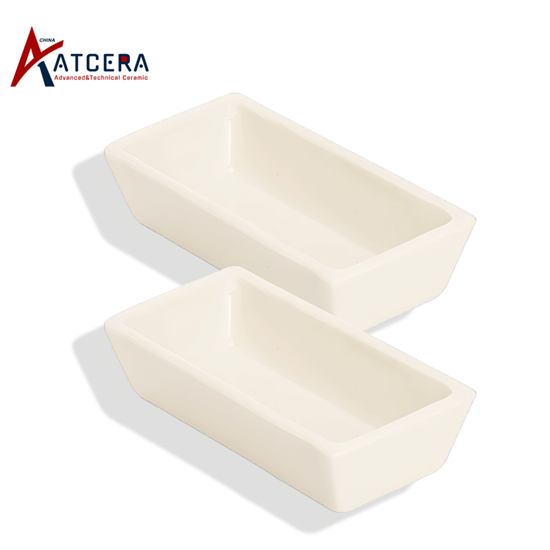

Application Fields of Ceramic Crucibles for Melting

The versatility of ceramic crucibles for melting has led to their widespread adoption across various industries. In the metallurgy sector, they are employed for the melting of precious metals and alloys, owing to their ability to withstand extreme temperatures without degradation. Similarly, in the glassmaking industry, ceramic crucibles are preferred for their chemical inertness and ability to maintain purity during the melting process. Furthermore, they find applications in the semiconductor industry for the precise melting of materials required for chip fabrication.

How to Select the Right Ceramic Crucible for Your Project

Choosing the appropriate ceramic crucible for your specific application is crucial. Factors such as the melting temperature required, the material being melted, and the desired crucible lifetime should be considered. Additionally, the crucible's compatibility with the melting environment and any specific requirements for heat retention or dissipation should be taken into account. By understanding these parameters, one can ensure the selection of a ceramic crucible that meets the project's needs and optimizes performance.

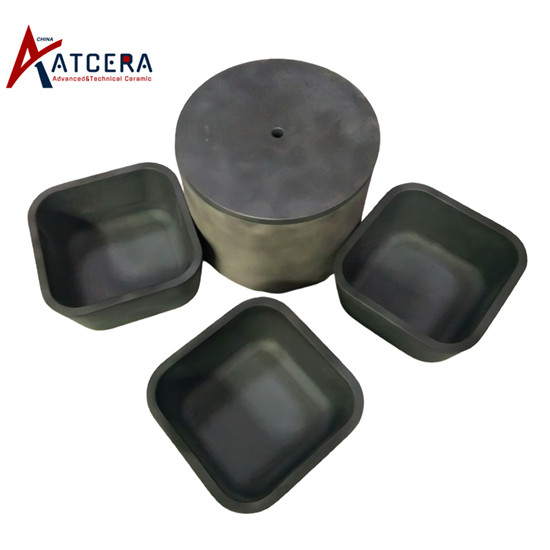

Manufacturing Process of Ceramic Crucibles for Melting

The manufacturing process of ceramic crucibles for melting is a highly specialized and intricate one. It begins with the selection of high-grade raw materials, by precise powder processing techniques to achieve the desired chemical composition and particle size. The powder is then shaped into the crucible's desired form using advanced molding methods. The crucible undergoes rigorous sintering and firing processes to achieve the required density, strength, and porosity. Finally, a series of quality checks ensures that each crucible meets stringent performance standards.

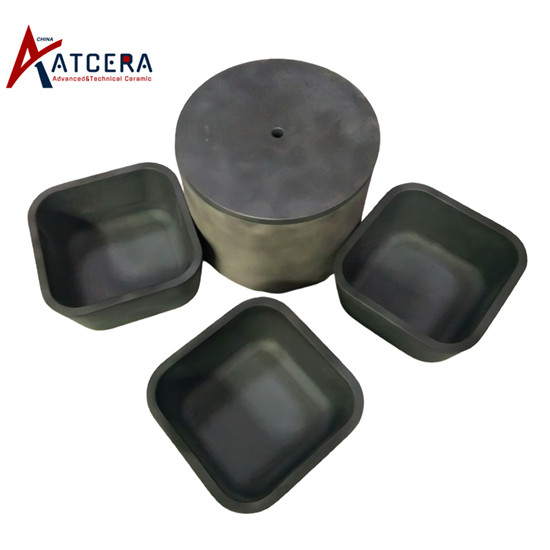

Fallstudien und Erfolgsgeschichten zur Verwendung von Keramiktiegeln zum Schmelzen

Zahlreiche Fallstudien und Erfolgsgeschichten unterstreichen die Vorteile der Verwendung von Keramiktiegeln zum Schmelzen. Ein Beispiel hierfür ist ein führendes Metallurgieunternehmen, das seine herkömmlichen Tiegel durch Keramiktiegel ersetzte. Die Umstellung führte zu erheblichen Verbesserungen bei Energieeffizienz, Materialreinheit und Tiegellebensdauer, was zu erheblichen Kosteneinsparungen und einer Produktivitätssteigerung führte. Ebenso konnte ein Glashersteller durch die Verwendung von Keramiktiegeln eine höhere Produktqualität und weniger Abfall erzielen und so seine Position auf dem Markt weiter stärken.

Abschluss

Keramiktiegel zum Schmelzen sind ein Beweis für die Konvergenz von Tradition und Technologie. Ihre einzigartigen Eigenschaften und ihre Vielseitigkeit haben sie in verschiedenen Branchen unverzichtbar gemacht, insbesondere in Europa und Amerika. Wenn man ihre Eigenschaften, Anwendungen und Auswahlkriterien versteht, kann man ihr volles Potenzial ausschöpfen und ihre Vorteile für bestimmte Projekte nutzen. Während sich die Industrielandschaft weiterentwickelt, werden Keramiktiegel zum Schmelzen weiterhin eine entscheidende Komponente für Innovation und Effizienz bleiben.